31 October 2024

31 October 2024

Rethinking low

carbon hydrogen

production by

chemical looping reforming

H2

Concept

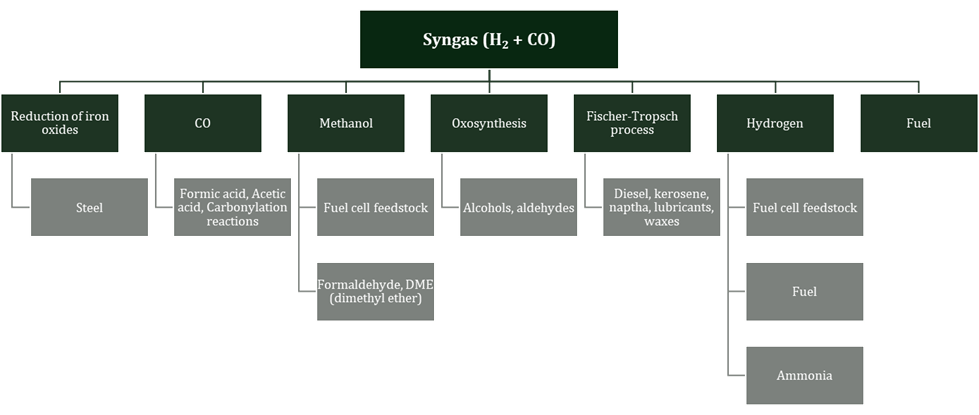

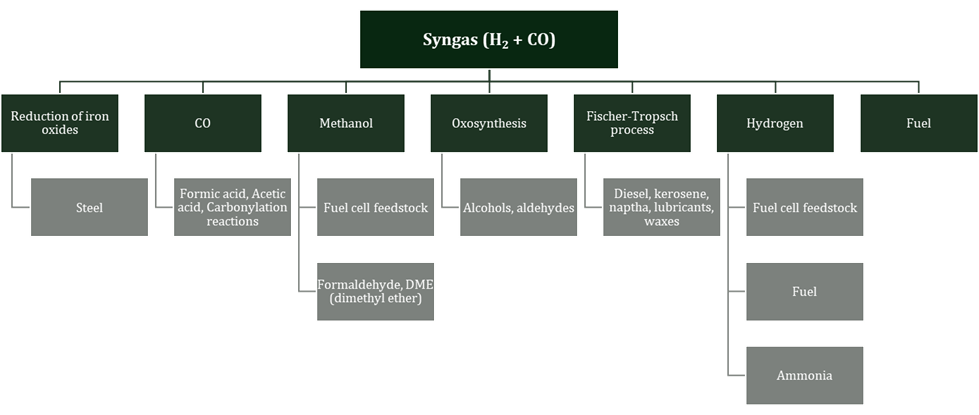

The University of Manchester will lead an international team to build and demonstrate a new technology to produce syngas and pure hydrogen with nearly zero direct carbon dioxide emissions.

Objectives

of the project

1

Timeline

Latest News and Publications

31 October 2024

31 October 2024

31 October 2024

31 October 2024